Soft metals play a critical role in various industries, particularly manufacturing and electronics. Their unique properties, such as malleability, conductivity, and resistance to corrosion, make them indispensable in creating products that demand precision and reliability.

Understanding Soft Metals

Soft metals are those that are generally easier to deform under stress. They typically have lower hardness levels compared to other metals, making them more malleable and ductile. This means they can be stretched or shaped without breaking, an essential property in both manufacturing and electronics. Despite their “soft” nature, these metals are integral to some of the most robust and technologically advanced applications.

The term “soft metal” can sometimes be misleading, as it doesn’t necessarily imply weakness. Instead, it highlights these metals’ ability to undergo deformation or to be worked into different forms with ease. When utilizing soft metals in manufacturing, referring to a reliable CNC machining cost guide is crucial for balancing cost efficiency with quality. This makes them ideal for various applications, from intricate circuitry to structural components.

Common Soft Metals in Manufacturing

Aluminum

Aluminum is one of the most widely used metals in manufacturing. Although not the softest metal, it is incredibly versatile and lightweight. Aluminum’s high malleability allows it to be easily shaped, while its corrosion resistance ensures durability. It is commonly found in aerospace components, automotive parts, and packaging materials like foil and cans. Aluminum is also extensively used in electronics, particularly in heat sinks and casings, due to its excellent thermal conductivity.

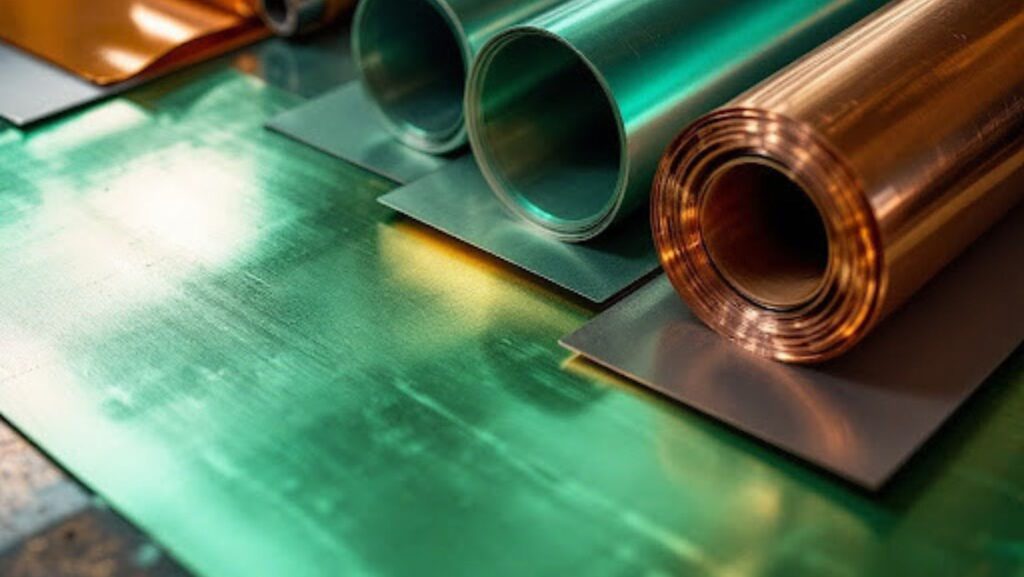

Copper

Copper is another standout metal when it comes to manufacturing and electronics. Known for its outstanding electrical and thermal conductivity, copper is a staple in electrical wiring, circuit boards, and connectors. It is also relatively soft and malleable, making it easy to shape and integrate into different systems. In manufacturing, copper is extensively used in plumbing systems, roofing, and electromagnetic shielding. The demand for copper in the electronics industry is particularly high due to its unparalleled ability to conduct electricity efficiently.

Lead

Lead is a soft metal with a low melting point, which makes it highly adaptable in various manufacturing processes. Despite being phased out in some applications due to health concerns, lead remains important in specific industries. It is commonly used in batteries, especially lead-acid batteries, radiation shielding in medical and industrial equipment, and in some soldering applications. Lead’s density and resistance to corrosion make it a valuable material in applications where weight and durability are important.

Tin

Tin is one of the softest metals, with a history of use dating back thousands of years. It is most commonly known for its role in creating alloys, such as bronze (tin and copper) and solder (tin and lead). Tin’s corrosion resistance makes it particularly useful in coating other metals to prevent rust. It is widely used in food packaging, particularly in tin-plated steel cans, soldering electronics, and manufacturing alloys for specific mechanical properties. Its versatility and non-toxic nature (in most applications) keep tin relevant in both traditional and modern industries.

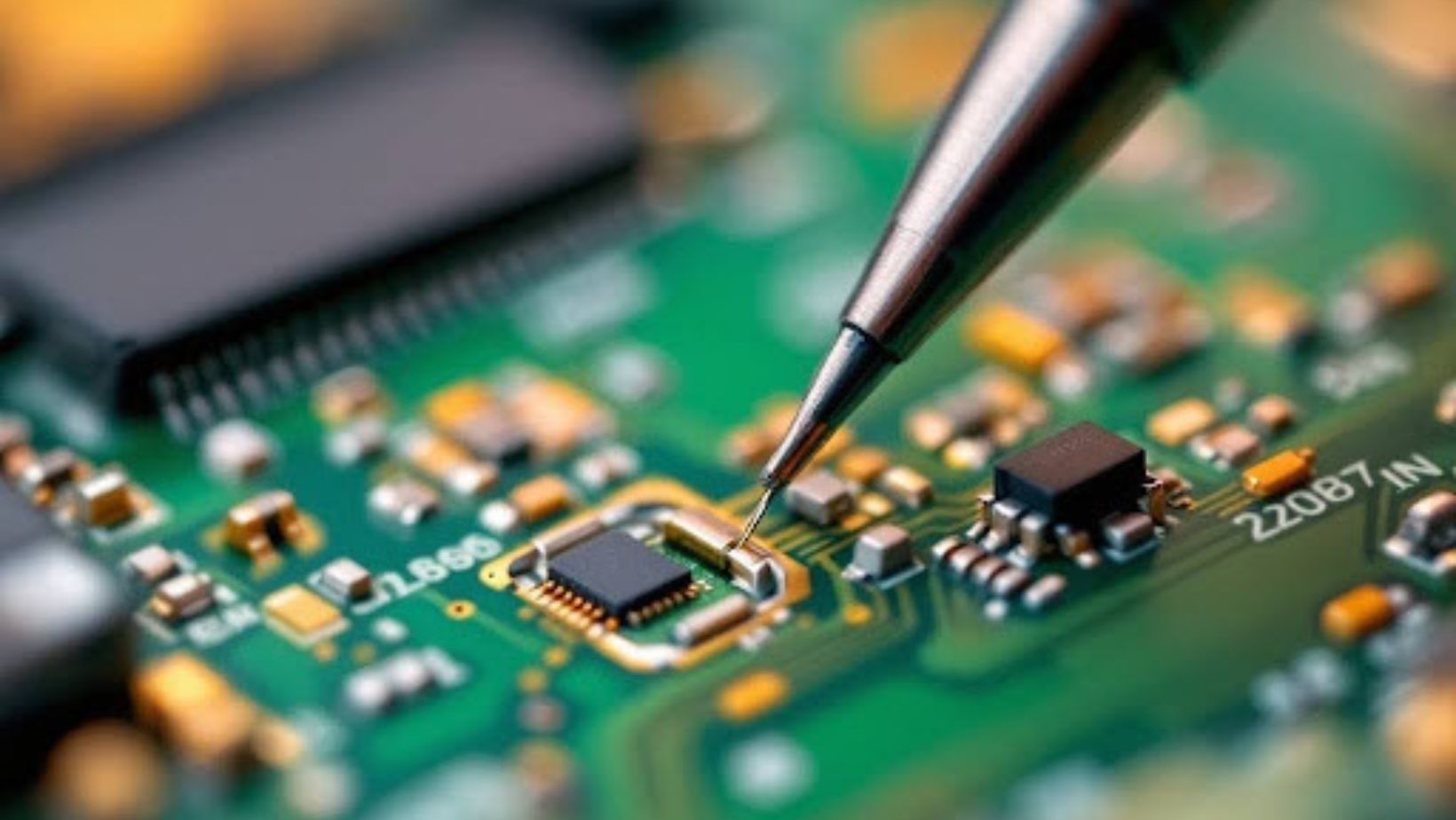

Soft Metals in Electronics

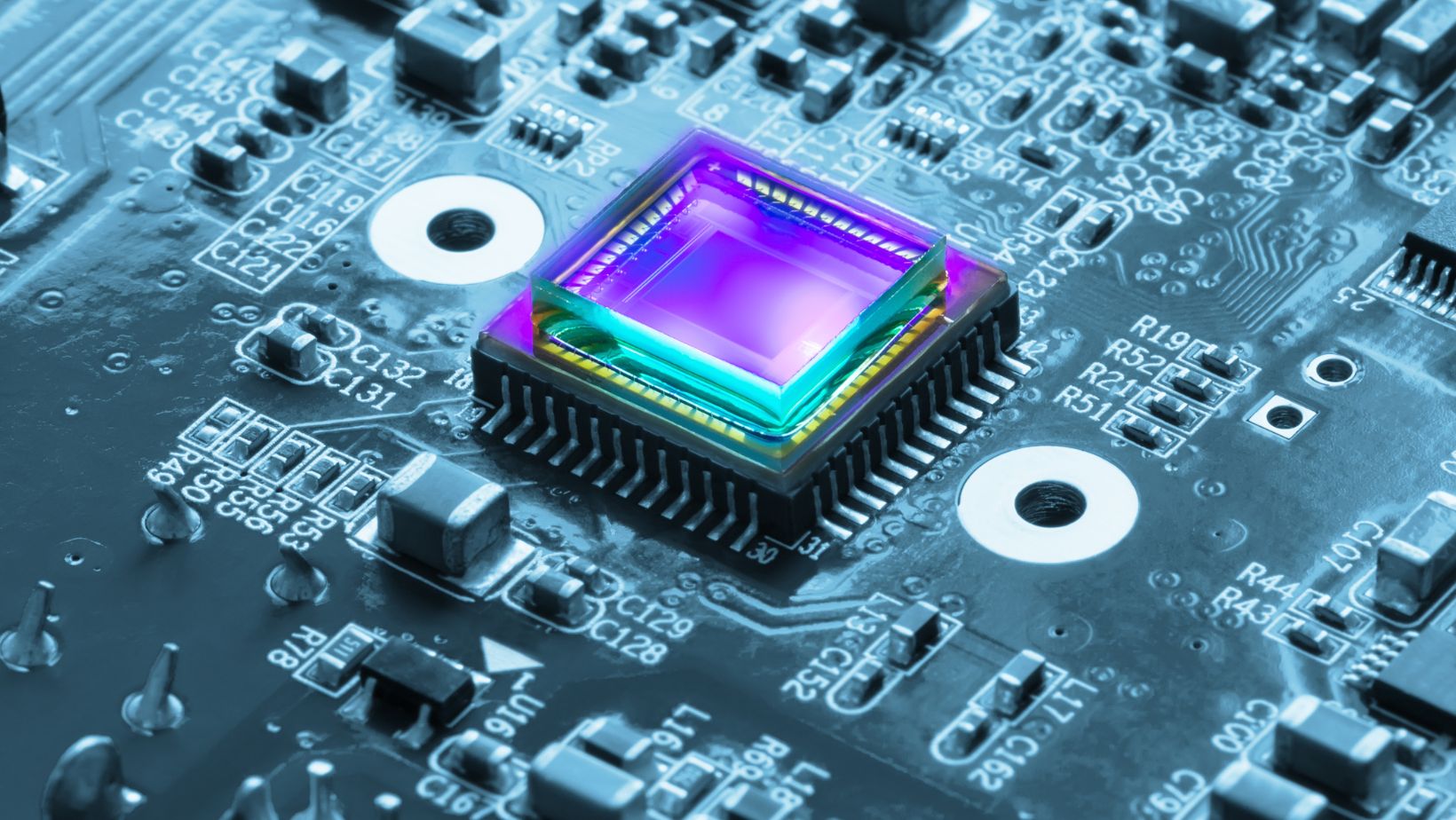

Gold

Gold is a precious metal known for its softness, conductivity, and resistance to corrosion. While its value often overshadows its practical uses, gold is an indispensable material in electronics.

It is used extensively in coating connectors and terminals for enhanced conductivity, microchip production, and components in aerospace and high-reliability electronics. The softness of gold makes it easy to work with while ensuring exceptional performance in sensitive electronic devices.

Silver

Silver holds the title of the best conductor of electricity and heat among all metals. This property, combined with its malleability and ductility, makes silver a key material in electronics manufacturing. Although less soft than gold, silver is still considered a soft metal. It is widely used in electrical contacts and switches, conductive inks for printed electronics, and solar panels. Silver’s high conductivity and reliability make it indispensable in modern electronic devices.

Indium

Indium is a relatively lesser-known soft metal but plays a crucial role in the electronics industry. It is often used in touchscreens, LCDs, and photovoltaic panels. Indium’s malleability and ability to adhere to other materials make it ideal for these applications. Key uses of indium include indium tin oxide (ITO) coatings for touchscreens and displays, solders in electronics with specific requirements for low melting points, and thermal interface materials for high-performance electronics. Indium’s unique properties make it a rising star among soft metals in electronics.

Why Are Soft Metals Preferred in Electronics?

The choice of soft metals in electronics is not arbitrary. Their properties offer distinct advantages that are hard to replicate with harder or less malleable materials. Soft metals can be easily shaped into wires, thin sheets, or intricate components. Many soft metals, like gold, silver, and copper, are excellent conductors of electricity and heat, making them essential for reliable electronic connections. Additionally, metals like gold and tin resist oxidation, ensuring durability and performance in harsh conditions. Soft metals often form strong bonds with other materials, improving the efficiency and reliability of electronic systems.

Conclusion

Soft metals have cemented their place in the world of manufacturing and electronics. From the ubiquitous copper in electrical wiring to the luxurious gold in high-end electronics, these materials are integral to countless applications. Their unique properties, such as malleability, conductivity, and corrosion resistance, make them indispensable in creating reliable and efficient products.

As industries evolve and sustainability becomes a pressing concern, the significance of recycling soft metals and developing innovative alloys cannot be overstated. The integration of these metals in cutting-edge technologies like nanotechnology and renewable energy solutions further underscores their importance.

Soft metals are not merely materials of the present but are key to the future of industrial and technological advancements. If you’ve ever considered their diverse applications, it’s clear that their adaptability and functionality make them irreplaceable across various sectors. With ongoing research and innovations, their role will undoubtedly expand, shaping a more efficient and sustainable world.

More Stories

Casinos Not on GamBlock (2025): Bypassing Blocks, Reclaiming Control

Personalized Mother’s Day Gifts That Are Trending for All the Right Reasons

The Hidden Risks of DIY TV Wall Mounting