Pogo Pin Connector has emerged as a trusted choice in the realm of electrical connectivity. Distinguished by their spring-loaded pin design, these connectors offer a unique blend of reliability, precision, and adaptability. Whether it’s for compact consumer electronics, cutting-edge medical devices, or rugged automotive systems, pogo pin connectors are a go-to choice for engineers and designers seeking robust performance in challenging conditions.

This article dives into how the pogo pin connector compares and measures up against other connector types. By exploring their strengths, limitations, and practical applications, you’ll gain the insight needed to determine if these connectors are the right fit for your specific needs.

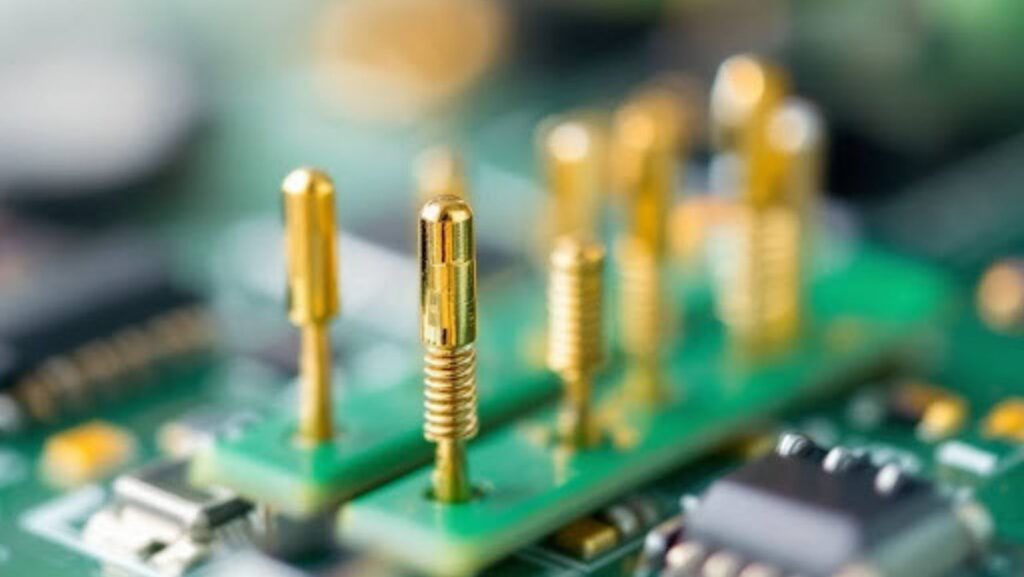

What Are Pogo Pin Connectors?

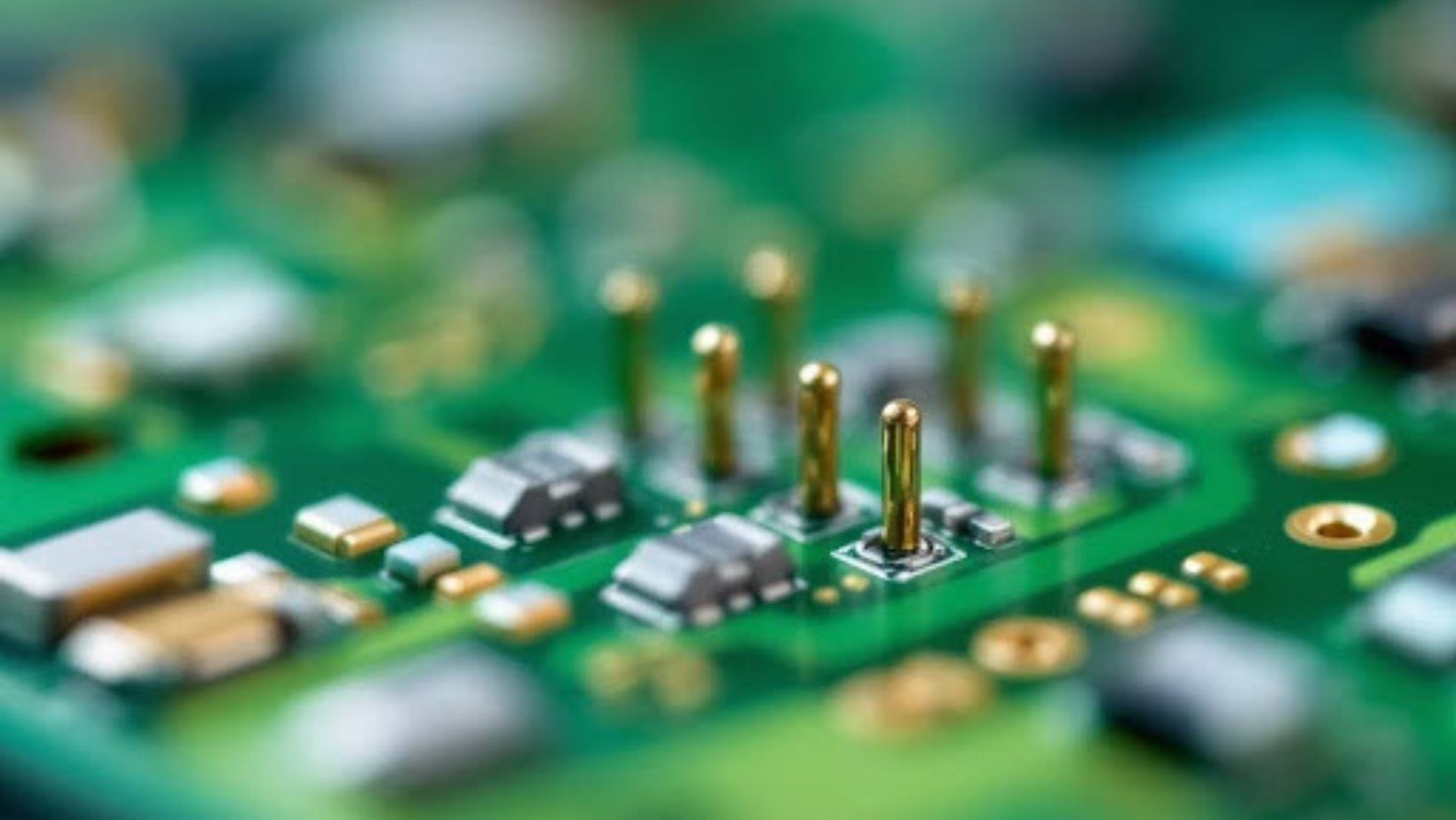

Pogo pin connectors consist of spring-loaded pins housed within a barrel. The spring mechanism allows the pins to compress and maintain contact under varying conditions, ensuring a stable and reliable electrical connection. These connectors are often used for applications that require repeated connections and disconnections or where space constraints are critical.

Typical applications for pogo pin connectors include:

- Charging docks for mobile devices

- Battery connections

- Testing and measurement equipment

- Wearable devices

The durability and compact nature of pogo pin connectors make them ideal for applications requiring precision and reliability.

Advantages of Pogo Pin Connectors

Durability and Longevity

Pogo pin connectors are designed to withstand thousands of mating cycles, making them highly durable compared to traditional connectors. This longevity is particularly important in applications where frequent connections and disconnections occur. The spring mechanism, crafted from robust materials, minimizes wear and tear, ensuring consistent performance over time, even in demanding environments such as manufacturing and testing facilities.

Compact Design

The small form factor of pogo pin connectors is a significant advantage in applications where space is limited. Their design allows for efficient use of available space in compact devices like wearable technology and handheld medical equipment. The ability to deliver reliable performance without occupying much space enhances their appeal in modern, minimalist product designs.

Reliable Contact

The spring-loaded design ensures consistent and reliable contact, even in environments subject to vibration, shock, or other dynamic conditions. This reliability is crucial for applications such as automotive systems, where stable connections are non-negotiable. Additionally, the spring mechanism accommodates slight misalignments, further enhancing contact reliability.

Customization

Pogo pin connectors can be customized to meet specific requirements, including pin length, diameter, and plating material. This adaptability enables manufacturers to tailor connectors to unique application needs, such as high-precision medical devices or rugged industrial tools. Customization options also extend to pin configurations, allowing for optimized performance in specialized setups.

Disadvantages of Pogo Pin Connectors

Cost

One of the main drawbacks of pogo pin connectors is their cost. The precision engineering and high-quality materials required for their spring-loaded design often make them more expensive than standard connectors. While this cost is offset by their durability and reliability, it may still be a deterrent for budget-sensitive projects or large-scale deployments.

Current Capacity

Pogo pin connectors typically have lower current-carrying capacity compared to other connector types. This limitation makes them less suitable for high-power applications, such as heavy industrial machinery or high-current automotive systems. Developers must carefully evaluate their power requirements before opting for pogo pin connectors.

Susceptibility to Debris

The spring-loaded mechanism can be sensitive to debris and contamination, potentially affecting performance. Dust, dirt, or other particles can compromise the movement of the spring or impede electrical contact. Proper sealing, regular maintenance, or the use of protective enclosures is often necessary to mitigate this vulnerability, especially in harsh environments.

Comparing Pogo Pin Connectors to Other Connector Types

Pogo Pin Connectors vs. Standard Pin-and-Socket Connectors

- Durability: Pogo pin connectors excel in durability for repeated mating cycles, whereas standard connectors may wear out more quickly.

- Cost: Standard pin-and-socket connectors are generally more affordable.

- Applications: Pogo pins are ideal for compact and precise applications, while pin-and-socket connectors are better suited for higher current requirements.

Pogo Pin Connectors vs. Spring-Loaded Clips

- Reliability: Both connector types offer reliable connections, but pogo pins provide more precise alignment.

- Flexibility: Spring-loaded clips are often used for temporary connections, whereas pogo pins are suitable for both temporary and permanent use.

- Form Factor: Pogo pins are typically smaller and more versatile in design.

Pogo Pin Connectors vs. Magnetic Connectors

- Ease of Use: Magnetic connectors offer quick and effortless connections, often preferred for consumer electronics.

- Durability: Pogo pins generally have a longer lifespan in terms of mating cycles.

- Reliability: Magnetic connectors can sometimes disconnect unintentionally, a drawback not typically associated with pogo pin connectors.

Pogo Pin Connectors vs. Edge Connectors

- Space Efficiency: Pogo pins have an advantage in compact designs, while edge connectors are better for applications requiring large-scale connections.

- Cost: Edge connectors are often more economical.

- Applications: Edge connectors are commonly used in printed circuit boards (PCBs), whereas pogo pins are more versatile.

When to Choose Pogo Pin Connectors

Pogo pin connectors are an excellent choice for applications that require frequent connections and disconnections, compact designs, and reliable performance under dynamic conditions. They are particularly useful in:

- Wearable technology

- Charging and docking stations

- Automated testing systems

- Medical and diagnostic devices

However, if cost or high current capacity is a primary concern, other connector types may be more suitable.

Conclusion

Pogo pin connectors stand out for their durability, compactness, and reliability. While they may come with higher costs and certain limitations, their unique spring-loaded design makes them indispensable in many precision and high-performance applications. Comparing them to other connector types highlights their specific advantages and drawbacks, helping you decide when and where to use them.

As technology continues to advance, the demand for versatile and reliable connectors like pogo pins is expected to grow. By understanding their strengths and limitations, you can choose the right connector for your specific needs and ensure optimal performance in your applications.

More Stories

VR Technology in Live Dealer Games Could Enhance Social Interaction and Player Experience

Finest Tips To Make Your Bankroll Last Longer When Playing Online Slots

Tweaking Your Gadgets for the Ideal Gaming Experience